My Story

I was recently asked by someone after some discussion of life's hurdles in trying to get people to understand the way I go at things, “how did you get to be this way?” One's view of the world of course develops over a life time, but there are always a few keys that will have steered us in our present direction. For me, I would have to say there were three main things- one was having loving parents who provided a stable home and upbringing, another, stemming from the first, was being fortunate enough to get a first-rate engineering education at Carnegie-Mellon and Princeton, and the third and somewhat unique was my initial entry into the working world of adulthood by my employment at Lawrence Phelps and Associates. My dad always said it was good to learn to write, to be able to express one's thoughts, so here I go...

Often when I mention I used to work at a company that built pipe organs, I am met with a sort of blank “oh”. I realize that for nearly all Americans, the pipe organ is a dismal memory of some whiny-sounding organ tucked away in the walls of a musty church, not a free-standing precision musical instrument capable of nuance. “I don't know much about them, but I guess we have a good one in our church”. For me, my understanding is quite different, and so to tell the story, let's go back to the beginning. Didn't someone say that was a very good place to start?

When I was very young a friend of my father's had given him a recording of

E. Power Biggs playing “Bach at Zwolle”.

I was taken with that record and listened to it enough that I nearly wore it out.

(My mom will back me up on this!)

Inside the record sleeve there were drawings of the old city of Zwolle

and some photos of the church and the organ.

I thought the organ was the most beautiful and splendid thing ever made

(even though it was made by a man with a funny name- Arp Schnitger);

there was a little black and white photo and I can still to this day remember it-

I could probably draw it from memory.

The record included four major Bach organ works and I loved the mood of the music and the sound;

it was in a sense my fantasy land.

When I was very young a friend of my father's had given him a recording of

E. Power Biggs playing “Bach at Zwolle”.

I was taken with that record and listened to it enough that I nearly wore it out.

(My mom will back me up on this!)

Inside the record sleeve there were drawings of the old city of Zwolle

and some photos of the church and the organ.

I thought the organ was the most beautiful and splendid thing ever made

(even though it was made by a man with a funny name- Arp Schnitger);

there was a little black and white photo and I can still to this day remember it-

I could probably draw it from memory.

The record included four major Bach organ works and I loved the mood of the music and the sound;

it was in a sense my fantasy land.

The grandfather of a boyhood friend of mine owned a local organ building company in Erie. Our local Lutheran Church at one point was interested in an organ and so my mother, brother and I got a personal tour of the factory. At the end the owner played a short hymn on an organ that was just being finished; I was completely amazed- this was the first time I had ever heard an organ live; there was so much more to the sound than the monaural record I had at home. I was probably 12 at this time and thought this was just the neatest thing in the world.

|

| Launching a model rocket I designed... about 3 years after this photo was taken I was working at Phelps. |

At the beginning of the next summer I promptly went down to apply for a job after school let out,

hoping something might work out. I had read in the paper about the company being

under new management by some guy named Lawrence Phelps.

I knew nothing about him, but there was a very interesting

article in the Erie Times my brother found (I only read comics) about the company having built the first

mechanical-action pipe organ being sent off to an Abbey in Northern England.

I was impressed since I knew that it was really a tracker organ like the one in Zwolle.

The Erie public library had a number of books on the organ and I

had looked at many of them.

As I sat in the office nervously filling out my job application,

trying to list things I'd done that would warrant employment

(I made a grandfather clock with all-wooden gears in high-school woodshop- would that count?)

I remember looking

out of the corner of my eye in awe (I didn't want to stare)

at the practice organ sitting in the office and seeing the roller bars for

the pedal.

So that was what those things looked like!

I remember reading and seeing drawings

about them but hadn't actually seen what a mechanical action system looked like for real.

Shortly after that I was informed that they would take me on for the summer

and I would even get paid $2.10 an hour.

I was ecstatic;

it sure beat trimming grass!

I remember looking

out of the corner of my eye in awe (I didn't want to stare)

at the practice organ sitting in the office and seeing the roller bars for

the pedal.

So that was what those things looked like!

I remember reading and seeing drawings

about them but hadn't actually seen what a mechanical action system looked like for real.

Shortly after that I was informed that they would take me on for the summer

and I would even get paid $2.10 an hour.

I was ecstatic;

it sure beat trimming grass!

I started my first day making tuning slides, cutting out and rolling up thin sheet aluminum. Everyone was very nice and helpful to me, showing me how to do the job correctly. I remember being so amazed and proud of what I was making, after all if pipes didn't have tuning slides, the organ wouldn't sound very good, would it? Somewhere very early on I was given some literature written by this Mr. Phelps fellow about organs. I read it over several times and started to get the impression he was really knowledgeable about organs and what he wanted to accomplish. I was even more excited to read about his incorporation of historic organ building principles and that he too had heard about this Arp Schnitger fellow. How much better could this get?

This was truly fun and inspiring for me, to be able to build organs. I had always liked making things as a kid: model trains, cars and rockets being my specialty. Many look back at the 60's and 70's as a transitional and tumultuous time for the country, but if you didn't do drugs, it really was a great time to grow up. It seemed that there was a sense of progress; the space race made design and engineering a profession to aspire to. If I wasn't going to build organs I was going to be an astronaut. I saw my brother's second grade teacher at my father's retirement in '97, and she said in many ways it was a great time in terms of education. She felt this way because few mothers worked outside the home, divorce was low, and teacher's weren't unionized. At any rate, I felt comfortable and that I could contribute in some way to what the company was trying to do.

Upon showing interest in Mr. Phelps' articles, I was rewarded with more articles to read. I began to learn more about the French Classical organ, the romantic period and the effect that had on the organ, and eventually the rise of the organ reform movement. It all sounded so wonderful and it was hard to believe I was right in the middle of it.

Being 16 and now entering my senior year of high school, my summer work experience had taught me a lot. It was a great first-job experience, something that had meaning and purpose. Summer jobs of lawn mowing and flipping hamburgers seemed so insignificant compared to what I had the opportunity to learn about. The first organ built in North America shipped to England? The Abbey's 1300th anniversary was a significant enough event that HRM Queen Elizabth attended events and visited the organ. Walking in for work in the morning with the smell of sawdust hanging in the air was so intoxicating. I can still hear the creak of the wooden floors and the sound of Paul Harvey telling us the rest of the story during lunch time. (28 years later, I still “brown-bag” my lunches at work.)

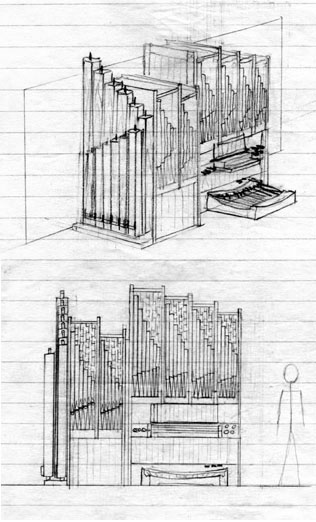

|

| Modified Phelps Practice Organ design. Added a 4' Principal. Wish I had one in my house! |

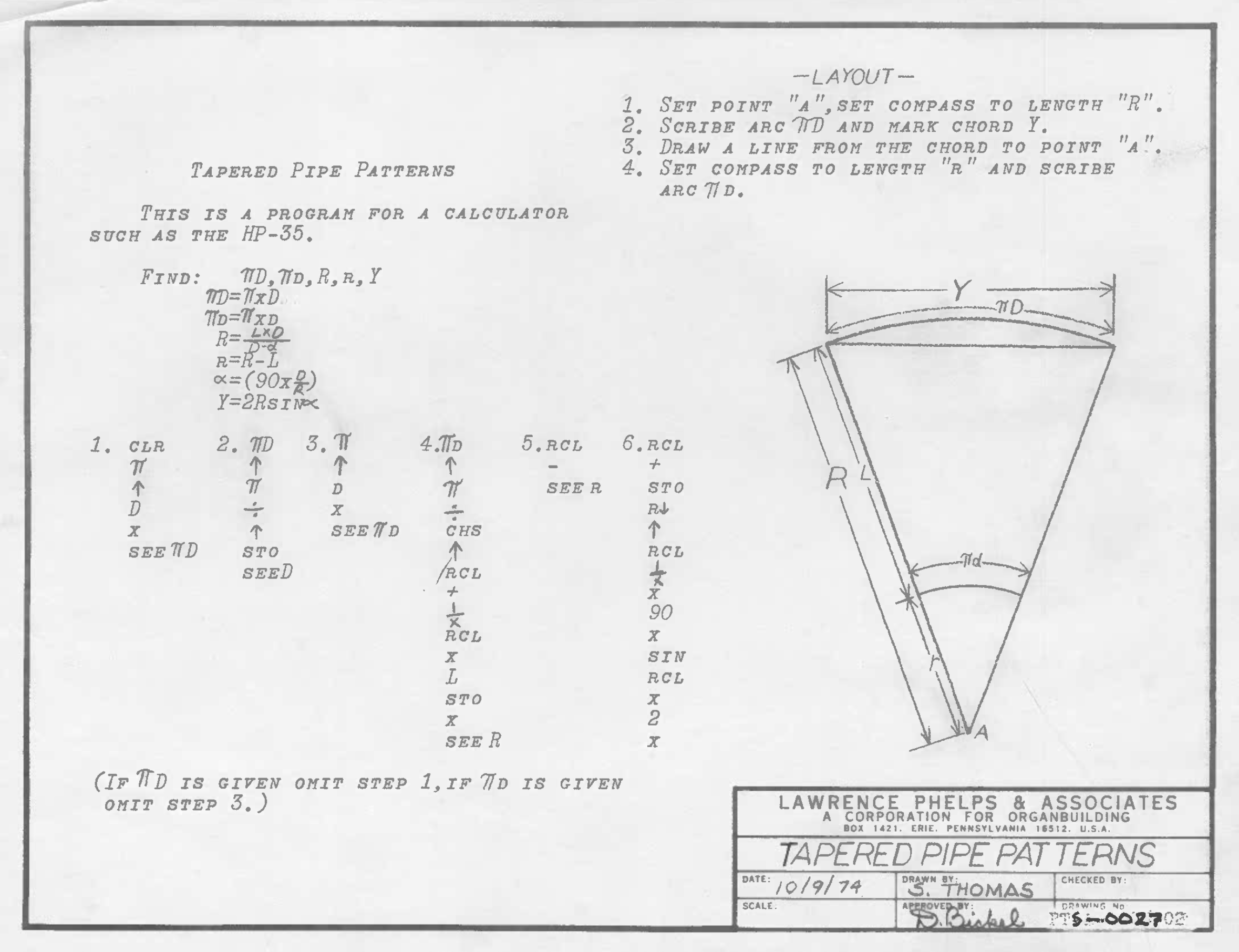

Working in the pipe shop, I had been given the responsibility of laying out the tapered pipes and cutting them out. Because each organ was scaled for the individual room for which it was being built, most tapered stops were not built from patterns. Each “cone”, whether it be a foot, trumpet, nazard, etc. had the basic top and bottom diameters and length defined. To cut out the piece, you needed to lay it out flat, like a slice of pie, and know the arc radius for the top and bottom, and the length of the chord at the top to accurately draw the side. The time-honored method was to fudge and guess until you got it right. I wasn't doing very well with this and realized it was a trigonometric problem. My dad helped me figure out a formula for taking the input numbers and compute the number I needed to lay out the pipe. Mr. Phelps let me take his new HP-35 scientific calculator home over a weekend to see if I could figure out a way to solve the problem on the calculator, after all it could do sines and cosines without having to look them up in a book. It took me a long time to figure out the Reverse-Polish notation (“RPN”) of Hewlett-Packard calculators, but with a help of one of the draftsmen, we wrote a “program”, or sequence of steps that would give me the results I wanted. After that, all the cut-outs were computed off the calculator. Pipes cut out of the metal stacked up flat on top of each, each note a bit smaller than the previous, making a beautiful set exemplifying logarithmic perfection. My career in “computer aided manufacturing” had begun.

|

| Drawing showing HP-35 steps to calculate the arc radii and chord. |

The HP-35 was the first scientific calculator with trig functions. There was an interesting article recently in Invention & Technology magazine about the historical nature of its development. I didn't realize all that at the time, but I was on the leading edge of technology. (Watching the film Apollo 13, I couldn't help notice how they had to calculate the trajectory updates with slide rules.) Through making many stops (all those lovely French mutation stops are tapered!) and going through the same key sequence over and over again, I was unwittingly learning the concepts of “ALU” (Arithmatic Logic Unit, the HP-35) and “CPU” (Central Processing Unit, that would be me!) that would later make learning computer architecture so personal and obvious. This little story was in essence what I learned in so many ways there- we used a new technology to change the way something had been done for the past 500 years because it made it better and more efficient. We didn't have to have a meeting or a committee to decide; it was the right thing to do, so you did it. Tradition was a guide from predecessors who were successful, not a practice by which to bind your thinking. (I should also say this started a relationship for me with computing and Hewlett-Packard that has lasted until the present day!)

In life we learn much through observation, not just the study of books. The fact that I had read library books and then got to see it all come to life made learning fun for me. I was not a bad student in high school, but I got mostly B's; a few C's and A's on occasion. When I entered Carnegie-Mellon as a freshman student I was quite sure I would not make it and it was just a matter of time before I flunked out. I was engaged in the standard engineering curriculum with calculus, physics, and metallurgy among my first year courses. Being worried about making it made me study hard; I would sit alone in my dorm room studying, listening to tapes I had made from LP's of Karl Richter playing Bach on a lovely Marcussen organ on a portable stereo radio/tape player my father had given me. When faced with the typical physics class problems like “what is the tension in the string”, I started making connections in my mind on why this was useful to know. After all, you had to know these things to safely suspend a trumpet en chamade out the front of an organ case, didn't you? Having real physical meaning tied to what I was studying made me study better, and I caught on to the idea of “getting it”. This was very important and would help me be a better student in coming years. It was one of life's moments where you were lead to the water's edge, were thirsty, and took the proverbial drink. No one could do it for you; you had to learn this yourself.

Returning to Phelps & Associates the next summer feeling a bit brighter following a successful start at college (I got A's!), I continued working in various facets of organ building. I had worked in various aspects of construction, slider and action mechanisms and some adjustment. We continued to build some wonderful instruments, and I had learned to play them a bit. In my freshmen year I was able to take organ lessons and get credit for my non-engineering electives, so that was a plus. Carnegie-Mellon has a nice 3-manual north-German style Phelps-Casavant which is where I took lessons, but I was not allowed to practice there, even late at night when the organ-major students were done. I thought that was terribly mean; they knew my interest in the instrument and connection with Phelps but still wouldn't budge. Playing was fun although I was not particularly good. My musical sensibilities were good but my technique wasn't so hot. I did get a chance to play in a master-class for blind Parisian organist and composer Jean Langlais when he came to Pittsburgh. I played the Prélude to his Suite Médiévale, and he started yelling about something when I was about 3/4 through the short piece. It turned out there was a mis-print in the music, so I was off the hook and continued to play the piece to the conclusion. I was the first student he didn't admonish for not holding the final chord long enough. The class was held at a church on the south side of Pittsburgh, which has a magnificent Phelps-Casavant instrument.

|

| Practicing in Erie after work, c. 1976. Just a kid back then! Phelps' French-terrace console design is my absolute favorite because the layout is visible and friendly. I always seemed to have a band-aid on my fingers... |

|

| My Grandmother and Aunt were in town, so they along with my Mom and brother (the photographer) came for a tour of the shop and a little recital at the Methodist Church. They heard all 20 minutes of my entire organ repertoire, with works by Buxteude, Couperin, Bach, Langlais, and Alain. |

By the next summer the Phelps organ for First United Methodist Church in Erie was completed and I was able to take lessons from Karen Keene, the organist there. It was quite a switch from the CMU approach to Bach, but made sense and I was able to practice on the organ there after work. This was wonderful because I could at least get a sense of what the organ was from a musical point of view, not just the design and construction of the instruments, which is admittedly fun and interesting in and of itself.

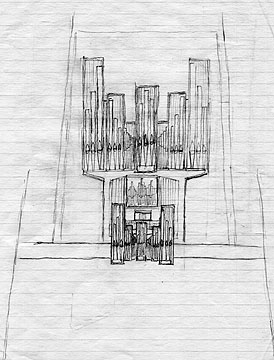

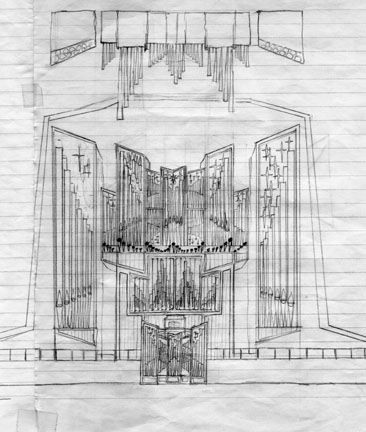

I continued to work at Phelps & Associates for a total of five summers, having the chance to work beyond the pipe-shop, learning about the electronics, mechanical action systems, and furniture-quality woodworking. I even toyed around with my own design, just sketching small instruments based on what I had seen at Phelps and also the work done in Denmark. I would occasionally work up the courage to talk to Mr. Phelps about some issue that was of seeming paramount importance to me, like what kind of materials we could make the tools from that we used to shape pipe mouths. We would talk about things and he would always listen with interest and encourage me to keep thinking and finding better ways to make pipes. I was pretty shy at the time but was glad when we talked; I felt good afterwards. I can't remember many of the specifics now, but I was at that age when you are eager to learn and absorb as much as you could.

Much of the work in a small company involves hands-on work. Shaping pipe mouths to the proper ratio was one of the first things I did that took some real craftsmanship. My initial attempts were frustrating; how did they get those perfectly shaped Gothic arches into those pipes? After some practice I started getting the hang of it and before long mine looked good. The trade is, to a degree, sculpture. Sculptors tools are used, maybe somewhat modified, to make pipes. This all led, several decades later for myself, to an appreciation of doing things hands-on. Engineers sometimes like to do things in an ideal environment, which can be misleading. One of my favorite quotes from Gleick's book Chaos describes the contrast between experimentalists and theorists: “Theorists conduct experiments with their brains. Experimenters have to use their hands, too. Theorists are thinkers, experimenters are craftsmen. The theorist needs no accomplice. The experimenter has to muster graduate students, cajole machinists, flatter lab assistants. The theorist operates in a pristine place free of noise, vibration, of dirt. The experimenter develops an intimacy with matter as a sculptor does with clay, battling it, shaping it, and engaging it.” Mr. Phelps did the final voicing of the instruments himself, by hand, on site. His wife, Gillian Weir, plays organs, which involves talents of the hand (and feet!) to the highest degree. It seems that as a society we try to avoid having to do things “by hand” at all costs, as if they were a bad thing. I learned that hands are very useful, not a tool for second-class citizens.

|

| Hypothetical small 3-manual French-Classical style organ. |

So much of what I do now stems from what I learned there. Until the advent of networked telephones systems and computers, the pipe organ was for centuries the most complex thing made by man. It preceded the industrial revolution and its motivations were of a more noble sort: it was a device of beauty, joy, humanity, pride, emotion and pleasure. Builders from centuries before built them because they wanted to; cathedrals bought them because they were incomparable and inspiring. I'm sure Arp Schnitger was a good business man, but I would have to imagine he thought of himself in terms of what he designed and built, and his actions were driven from an internal sense of what was right. Lawrence Phelps and his Associates were like this too, doing what they did from an internal sense of vision, each member of the team contributing from their area of strength. The beauty of what happened is that it just made sense; historical principles were used because they made sense and worked, not just because they were historical. If new material and technologies came along, they were readily adopted if they made sense and helped accomplish the mission, which in the end was to make music. I think as Americans we tend to have feature-itis and look for the single magic bullet that will solve all our problems. We like grand solutions. The problem is it's easy to forget what we were trying to do in the first place. Building organs is particularly susceptible to this, as organs are wonderful engineering projects. But if we forget what music is about, if our efforts fail to transport our minds to a better place, we have lost our way.

|

| Sketch of hypothetical large 3-manual organ. When I was a student at CMU, I would often go over to St. Paul's where they had a large 4-manual Beckerath organ. The building was large enough to have the acoustics to support the instrument, and the chamade Trompettes always would stand out even against full organ. This instrument was roughly Phelps' Tulsa organ re-packaged into 3 manuals and put into a large contemporary church. |

I recall having several phone conversations with Larry in the mid-90's.

I can't recall the reason I had tried to get in touch with him, but

we had connected on the phone after having been out-of-touch for 15 years.

The topic particulars escape me, but I remember after hanging up the phone reflecting on

how amazing was

his ability to see things as they were, in an honest and straightforward way, even after all the things he had been through.

It's remarkable how much of our thinking can be colored by our beliefs about something,

even if it's not correct and we know it.

The human mind has an incredible power to rationalize things and I suppose it's the flip

side of our ability to think abstractly and imagine things.

But I think I learned something about how to see clearly what is in front of me and not

be influenced by realities not there.

My colleagues at work consider me to be fairly creative; one friend says, when it comes to

“out-of-the-box” thinking, I had problems ever finding the box in the first place.

Much of that is the result of what I learned in my impressionable youth, that you think in terms

of where you want to go, not where you are.

I sometimes have this tendency to have difficulty getting along and trusting

colleagues implicitly until I know we are working off the same internal vision.

The freedom of mind it provides, reinforced over and over again in time as you grow older,

has shaped my being beyond what most have had the opportunity to learn.

© 2002 Steve Thomas